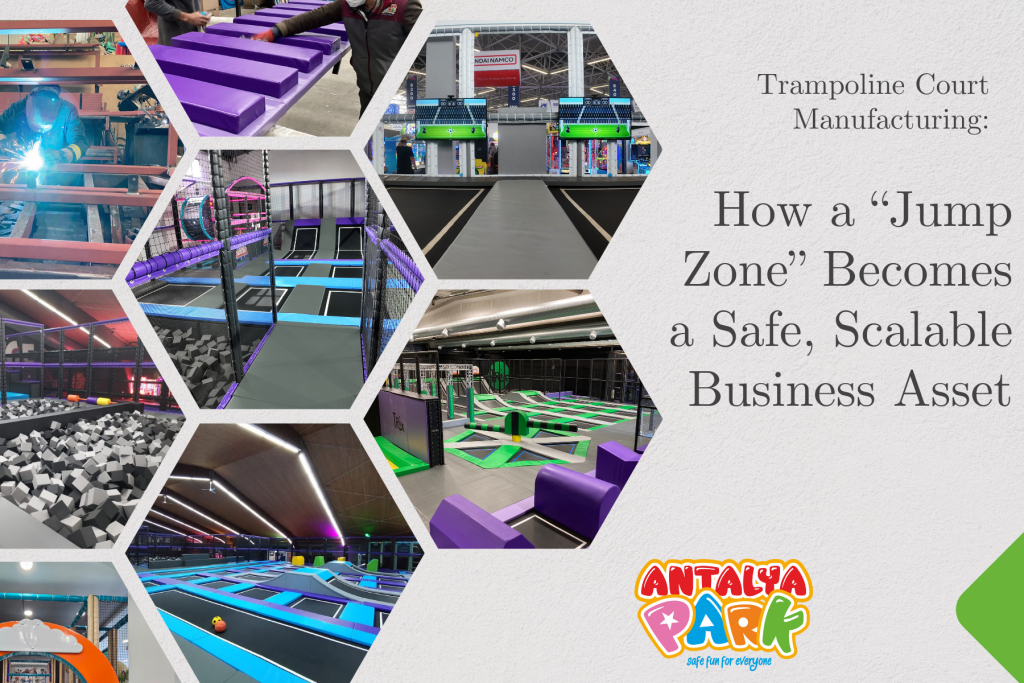

A trampoline area is one of the most effective ways to add high energy and strong “wow factor” to a venue—without building a full trampoline park. But even a compact trampoline zone is a high-load system. That’s why choosing the right Trampoline Area Manufacturer matters for safety, durability, and long-term business stability.

This article explains what a trampoline area manufacturer should deliver and what you should evaluate before investing.

1) What Is a Trampoline Area?

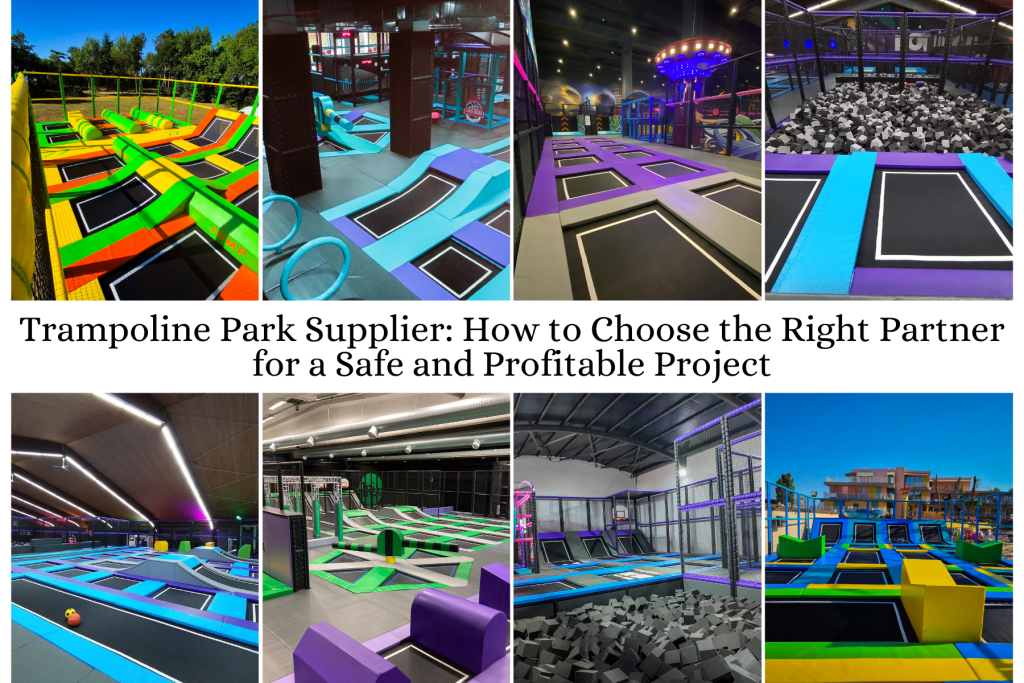

A trampoline area is a dedicated jumping zone inside a larger facility such as:

- soft play centers

- family entertainment centers (FECs)

- malls and leisure venues

- sports activity facilities

- hotels and resorts

Compared to a full trampoline park, it typically has a smaller footprint and a simpler attraction mix—but it still requires professional engineering.

2) What a Trampoline Area Manufacturer Should Deliver

A professional Trampoline Area Manufacturer should provide a complete, ready-to-operate system, including:

- custom layout planning for your venue and traffic flow

- engineered steel frame structure designed for dynamic loads

- jump bed system and correct tension distribution

- protective padding and safe perimeter design

- transition platforms and safe access routes

- technical drawings, project discipline, and installation planning

- maintenance guidance, spare parts, and after-sales support

If a supplier only sells “beds and pads,” you may face operational risks later.

3) Safety Engineering: The Core of the Product

Trampoline areas are physics-heavy environments. Safety depends on how the system controls energy and prevents accidents through:

- stable structural engineering and secure fixing points

- consistent bounce behavior and controlled tension

- durable padding that stays in position under heavy use

- safe edge design and barrier solutions to reduce impacts

- clear zoning logic to prevent uncontrolled collisions

- durable, non-toxic material choices and fire-resistant options for public venues

A serious manufacturer should be able to explain how these safety decisions are built into the design.

4) Why Trampoline Areas Perform Well as Attractions

A trampoline area works well commercially because it offers:

- instant excitement and easy-to-understand play

- strong repeat-play behavior (“one more round”)

- group appeal (siblings, friends, birthdays)

- high visual and social media value

Even in a smaller space, it can increase dwell time and improve the perceived value of the entire venue.

5) Installation and Long-Term Operation

A trampoline area is built twice: in engineering and on site. A reliable manufacturer provides:

- clear drawings and structured approvals

- organized packaging and installation guidance

- experienced installation support

- final inspection and structured handover standards

Long-term stability depends on inspections and service support. A good trampoline area manufacturer helps with:

- daily/weekly/monthly inspection routines

- planned replacement for high-wear components

- fast spare parts availability and responsive technical support

Downtime is lost revenue, so support is part of the investment.

Conclusion

Choosing a Trampoline Area Manufacturer is choosing the long-term performance of your venue. The right partner delivers safety engineering, durable materials, disciplined installation, and dependable after-sales support.

When these elements work together, a trampoline area becomes more than a feature—it becomes a reliable attraction point that increases repeat visits, strengthens customer trust, and supports sustainable revenue for years.